Who we are

Katoen Natie offers total solutions for specialty chemical producers, based on semi-industrial and engineering services. In addition to storage and handling we take care of all the value added services for your product, from blending and demetalizing to repackaging and optical sorting, and everything in between. In fact, we can manage your logistics and provide all the semi-industrial services that you need. So you can concentrate on your core business: your product. You benefit from having all these services under one roof, with a single partner to deal with, all over the world.

On 06.09.2018, Katoen Natie Specialty Chemicals organized its first dedicated Liquids Event! The specialized team gave insight in our services for handling liquids throughout the logistics chain. During this inspiring day, leading players in the chemical industry could discover the various possibilities we offer at our liquid handling terminals. Watch the after movie and get an insight yourself.

Storage

As a semi-industrial service provider, storage stays one of Katoen Natie’s core competences. This includes not only the physical storage but also the administrative processing. We position ourselves as a capacity provider, but we can accommodate smaller flows as well. Our transport and distribution systems merge seamlessly with your production flows and help to streamline your supply chain. In some cases we can even interface between your ERP and our Warehouse Management System.

All kind of hazardous and non-hazardous liquids can be stored in our tailor-made warehouses in several configurations (cans, drums, IBCs…). Besides the storage in our warehouses, a large fleet of ISO-tank containers is available for flexible storage of liquids. The necessary surrounding infrastructure is available as well.

Talk to an expert

Drumming

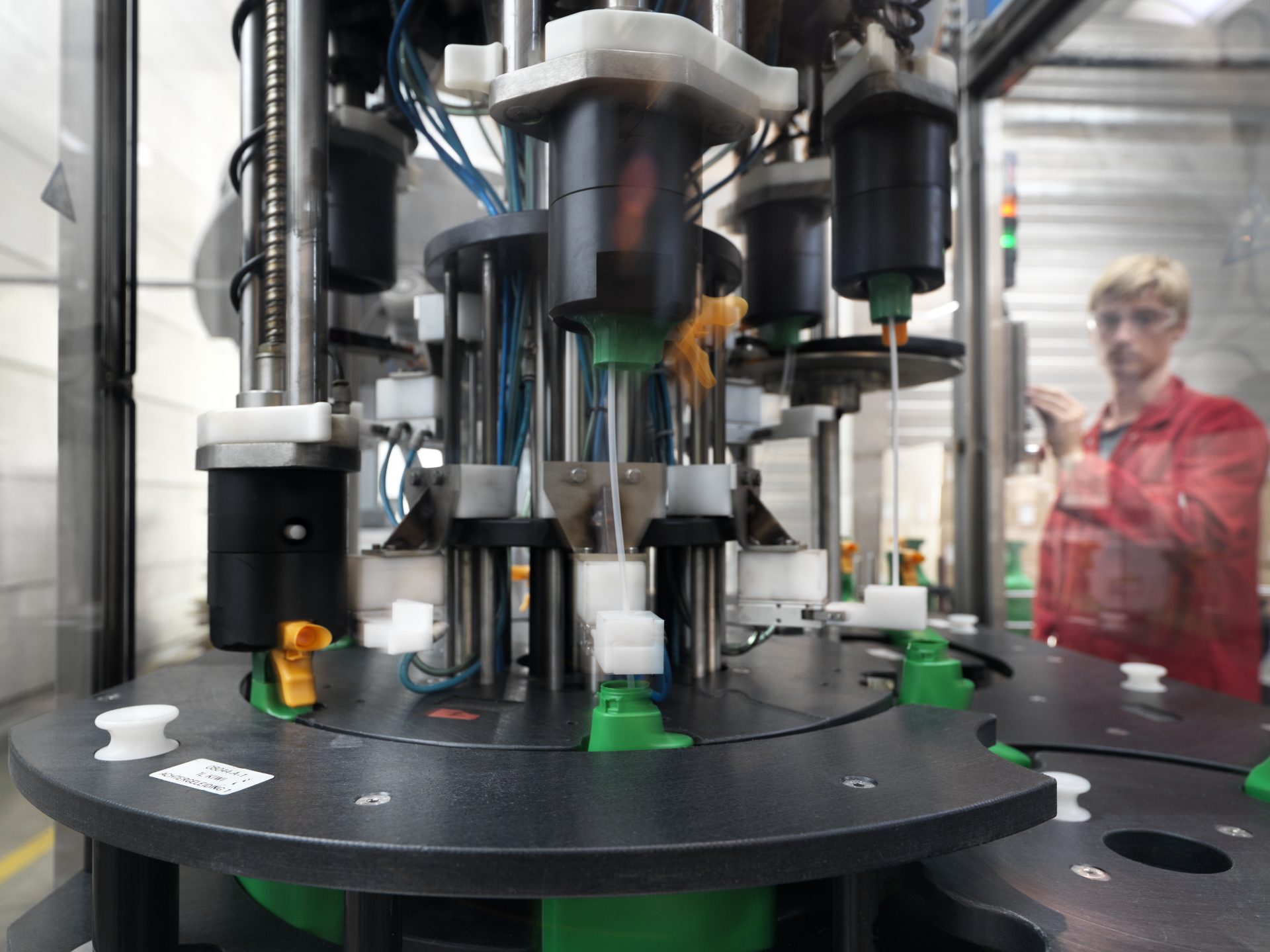

We optimize your flows of chemical liquids by implementing our high-tech drumming service.

We are able to handle any type of liquid, including:

- biodiesel

- surfactants

- polyols

- lubricants

- resins

- herbicides

- pesticides

and many more.

With our different semi-automated and automated filling lines we can repack your liquid products in almost any configuration, ranging from the smallest cans up to large bulk flows.

Talk to an expertCanning

Filling of cans is one of our core businesses. With different automated and semi-automated filling machines, we can fill out of IBC or tank container to 40ml bottles up to 5L bottles. Our machines are all equipped with tools to close the bottles with caps, providing them with front- and backlabels and print the necessary information on the bottle and boxes.

Thanks to our experienced operators and quality system, we can assure you receive the highest service level.

Talk to an expert

ISO tank container operations

Katoen Natie operates its own fleet of more than 1,400 tank containers. With offices in Antwerp, Houston and Singapore and a worldwide network of agents we are a NVOCC provider of tailor-made, global, door-to-door, bulk chemical forwarding services.

Tank Container Operations

Our staff is highly experienced in forwarding activities and hazardous cargo transport. We can provide extensive technical advice on the optimal handling and shipping of your chemical liquids. With our worldwide network of test, repair and cleaning stations, and hauliers, we organize intermodal transport, export & import shipments as well as document control to a high level of customer satisfaction. Alternative methods of transport, such as flexibags, can be organized upon request.

The High Heat expert

Our fleet is designed to cater to extensive high heating requirements. The tanks range in design temperature from 150 to 200 °C, ideal for transporting viscous liquids with high melting point or liquids that solidify at ambient temperature.

Fleet management services

Thanks to our expertise we can act as your partner in providing fleet management services. By organizing the loading, discharging, repair, cleaning, document control and forwarding we optimize your fleet condition and utilization.

Heating

Recently, Katoen Natie invested in a heating installation in Kallo, Antwerp. This investment doubles our capacity and offers the possibility to heat ISO tank containers with steam at various pressures, hot water and electricity.

All heating spots are equipped with temperature logging to provide accurate read outs of the heating process. Besides this, we are able to heat your products in drums or IBC’s in one of our hotboxes, reaching temperatures up to 90°C.

Talk to an expertBlending

You need a homogeneous product as raw material in your production process or to blend products for your end customer, and you don’t want to include this in your core business. Here Katoen Natie can be your partner. Starting from liquids, or liquids and solids, we can produce the requested blends. Raw materials can be processed under ambient temperature or preheated. Nitrogen coverage during the process is possible as well. Depending on the recipes we differentiate between:

-

- Solutions

- Dilutions

- Dispersions

- Pastes

For all of them particular equipment is available ranging from batch blenders to in-line blending technique. Volume-wise we can handle anything from small batches up to ISO tank level. Moreover the blends can be filled directly into the preferred recipient (small packaging, drums, IBCs, ISO tank, etc.).

Talk to an expert

Transloading

In order to optimize your flows of chemical liquids, we can transfer your liquids between different types of units. This includes transfer from drums and IBC into ISO tanks, from ISO tanks into ISO trailers and the other way around.

Transloading takes place in a contained environment. Before or after transloading, and depending on your particular needs, you can take advantage of our tank yard and warehouses to store your products.

Filtration

For certain sensitive applications, your product may require an enhanced purity level. Katoen Natie can use filtration systems in our liquid handling services to remove impurities.

Talk to an expert

Katoen Natie and Intergamma are now utilizing AutoStore, the world's fastest and most reliable order processing system per square meter, for e-commerce order deliveries to Intergamma's customers.

This cube-shaped automated system, comprising approximately 900 m³ and equipped with 20 robots, has been in operation since the end of September 2023 at Katoen Natie's logistics platform in Kallo, which is the largest "multi-customer" logistics platform in Europe. The installation and implementation are part of a joint future project between Katoen Natie and Intergamma, following the recent extension of their successful 10-year partnership by an additional 5 years. For Intergamma, the Benelux leader in the DIY market and currently in a strong growth phase, this means that all its e-commerce products can reach private consumers even faster and more efficiently. "For Katoen Natie, the expertise built with AutoStore is an additional incentive to attract new customers to our logistics platforms with innovative solutions," says Fernand Huts, Chairman of Katoen Natie.

Katoen Natie is implementing this goods-to-man automated storage and picking system for the first time at its Kallo logistics platform. This implementation is part of the shared desire of Katoen Natie and Intergamma to ensure they can continue to work together in a future-proof manner. Katoen Natie Engineering Solutions, Katoen Natie's in-house research department, is closely monitoring the process and operations, and is also exploring the opportunity to invest in additional AutoStore installations on other logistics platforms.

Katoen Natie and Intergamma are now utilizing AutoStore, the world's fastest and most reliable order processing system per square meter, for e-commerce order deliveries to Intergamma's customers.

This cube-shaped automated system, comprising approximately 900 m³ and equipped with 20 robots, has been in operation since the end of September 2023 at Katoen Natie's logistics platform in Kallo, which is the largest "multi-customer" logistics platform in Europe. The installation and implementation are part of a joint future project between Katoen Natie and Intergamma, following the recent extension of their successful 10-year partnership by an additional 5 years. For Intergamma, the Benelux leader in the DIY market and currently in a strong growth phase, this means that all its e-commerce products can reach private consumers even faster and more efficiently. "For Katoen Natie, the expertise built with AutoStore is an additional incentive to attract new customers to our logistics platforms with innovative solutions," says Fernand Huts, Chairman of Katoen Natie.

Katoen Natie is implementing this goods-to-man automated storage and picking system for the first time at its Kallo logistics platform. This implementation is part of the shared desire of Katoen Natie and Intergamma to ensure they can continue to work together in a future-proof manner. Katoen Natie Engineering Solutions, Katoen Natie's in-house research department, is closely monitoring the process and operations, and is also exploring the opportunity to invest in additional AutoStore installations on other logistics platforms.

Intergamma in a Growth Phase

In the Benelux, Intergamma is the market leader in the DIY industry with three brands: GAMMA Netherlands, GAMMA Belgium, and Karwei, which together operate 384 stores in Belgium and the Netherlands. "Ongoing developments in Intergamma's online channels have led to increased volumes," says Joost De Beijer, CEO of Intergamma. "The new investment in AutoStore in collaboration with Katoen Natie aligns perfectly with our strategy, in which e-commerce will continue to be crucial in the future while we simultaneously make our supply chain more sustainable. We aim to evolve into a 'one-stop shop,' where consumers can turn to GAMMA and Karwei to address their entire DIY project in one go and have their supplies delivered or picked up wherever they prefer." Intergamma expects that the investment will ultimately lead to increased capacity, flexibility, better reliability, and lower costs.

How Does AutoStore Work?

Bins with inventory are stacked 16 levels high next to and on top of each other within the grid. The grid is the customized aluminum rail system surrounding the bins and robots. Autonomous robots travel on top of the grid and continuously collaborate to retrieve stock for orders from the grid. They do this by lifting bins from the grid and rearranging them until they have the correct one. This bin is then presented at one of the 3 picking stations. The picker retrieves the goods from the bin and processes the order. The bin is returned to the grid. The algorithm ensures that stock for orders is always retrieved in the most efficient manner. This automation has no impact on existing jobs, as the pickers can now accomplish more with the same team. Additionally, it reduces picking errors, ensures continuous inventory management, optimal availability, and no single point of failure.

Intergamma in a Growth Phase

In the Benelux, Intergamma is the market leader in the DIY industry with three brands: GAMMA Netherlands, GAMMA Belgium, and Karwei, which together operate 384 stores in Belgium and the Netherlands. "Ongoing developments in Intergamma's online channels have led to increased volumes," says Joost De Beijer, CEO of Intergamma. "The new investment in AutoStore in collaboration with Katoen Natie aligns perfectly with our strategy, in which e-commerce will continue to be crucial in the future while we simultaneously make our supply chain more sustainable. We aim to evolve into a 'one-stop shop,' where consumers can turn to GAMMA and Karwei to address their entire DIY project in one go and have their supplies delivered or picked up wherever they prefer." Intergamma expects that the investment will ultimately lead to increased capacity, flexibility, better reliability, and lower costs.

How Does AutoStore Work?

Bins with inventory are stacked 16 levels high next to and on top of each other within the grid. The grid is the customized aluminum rail system surrounding the bins and robots. Autonomous robots travel on top of the grid and continuously collaborate to retrieve stock for orders from the grid. They do this by lifting bins from the grid and rearranging them until they have the correct one. This bin is then presented at one of the 3 picking stations. The picker retrieves the goods from the bin and processes the order. The bin is returned to the grid. The algorithm ensures that stock for orders is always retrieved in the most efficient manner. This automation has no impact on existing jobs, as the pickers can now accomplish more with the same team. Additionally, it reduces picking errors, ensures continuous inventory management, optimal availability, and no single point of failure.

Round the clock robots

Customers can place orders online until 9:00 PM, and Katoen Natie hands over the packages to the carrier by 11:00 PM, ensuring that the packages are delivered to the customer's doorstep the next day. While Katoen Natie sleeps at night, the robots keep working. During the night, they ensure that the fast-moving products of Intergamma are always located in the top "drawers" of the grid and are thus picked up the fastest. All e-commerce orders for Intergamma are transmitted directly to AutoStore through the Electronic Data Interchange (EDI) electronic data exchange system. AutoStore is also connected to Katoen Natie's existing packing automation. As a result, each box is automatically sealed after picking and is not touched until it is loaded.

Since September 25, a significant portion of Intergamma's products has been picked by AutoStore robots at Katoen Natie. However, starting from the end of October, the planned stock of Intergamma will also be stored in AutoStore. This will include more than 21,000 items distributed across 31,000 bins, with 6,528 of them subdivided into 4 compartments, bringing the total to 50,584 locations with stock.

Round the clock robots

Customers can place orders online until 9:00 PM, and Katoen Natie hands over the packages to the carrier by 11:00 PM, ensuring that the packages are delivered to the customer's doorstep the next day. While Katoen Natie sleeps at night, the robots keep working. During the night, they ensure that the fast-moving products of Intergamma are always located in the top "drawers" of the grid and are thus picked up the fastest. All e-commerce orders for Intergamma are transmitted directly to AutoStore through the Electronic Data Interchange (EDI) electronic data exchange system. AutoStore is also connected to Katoen Natie's existing packing automation. As a result, each box is automatically sealed after picking and is not touched until it is loaded.

Since September 25, a significant portion of Intergamma's products has been picked by AutoStore robots at Katoen Natie. However, starting from the end of October, the planned stock of Intergamma will also be stored in AutoStore. This will include more than 21,000 items distributed across 31,000 bins, with 6,528 of them subdivided into 4 compartments, bringing the total to 50,584 locations with stock.

Our Autostore in action on YouTube:

Our Autostore in action on YouTube: