Brexit

What’s the Brexit status?

In the nick of time the UK concluded a deal with the EU. As many details are still unclear, please contact us if you require insights or explanation. We submit each case to our in-house customs- and fiscal experts. This way we can assist you in finding the most optimal transport and/or storage solution.

How can we help you?

All our warehouses in Belgium are bonded warehouses, which are in custom approved zones. Objects can be stored in transit and are not subject to import duties and/or VAT. The other way around, in these warehouses we can also store objects with a free circulation status (VAT paid) and they keep their free circulation status in the EU.

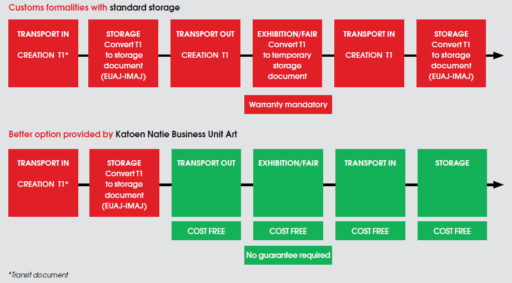

Katoen Natie has a unique position. Only at Katoen Natie are you allowed to remove art objects from these warehouses (e.g. for an exhibition or trade fair) while the objects remain bonded.

This means that the objects can travel throughout the EU free from import duties and/or VAT, to exhibitions and fairs, without any additional administration, guarantees or costs applying. The administration and cost structure surrounding the movement of your art are simplified/reduced to a minimum.

The simplicity of our set-up is explained in the graphic below:

Why store at Katoen Natie?

When you store your art collection in our depots, you can be sure that your objects can still easily travel the EU. This applies to both objects subjected to customs and objects which have the EU’s free circulation status, while saving you unnecessary costs and headaches.

Furthermore, we store your objects in world class facilities. We offer more than +250.000 sqft of art storage, which is:

- Hypersecure (INCERT3)

- Ecological (powered by wind mills & solar panels)

- Discrete and anonymous

- Climatized (ranging from ASHRAE AA+ to ASHRAE AA)

- ISO9001-2015 certified

- Inspected by all major Insurance players

- Competitively priced

- Situated in the heart of EU, close to major airport/seaport/transport hubs

- Private vaults or grouped storage

- Supported by an in house developed collection management system

Katoen Natie is a one-stop-shop, offering all services expected from a professional art logistics player, including art collection management, fine art transport, viewing/sales rooms, condition checks, photography, expo rooms, packaging, installation, courier services, …

Want to know more?

Get in touch with us to discuss your questions about Brexit, art transport or art storage. We already work with company collections, artists estates, museums, international collectors & galleries, foundations, … so chances are we can answer your particular questions with answers stemming from experience.

Please contact us at: ktn.art@katoennatie.com